Precision design

Yachting Developments' 3D printing division is delivering impressive results for their AC9F model

11 June 2020

One of Yachting Developments key selling points is its in-house capabilities and versatile offering across a broad number of fields including marine, architectural, residential and movie set work. The yard’s specialist composite team is complemented by its other dedicated divisions including the upholstery team and, most recently, the in-house 3D printing department.

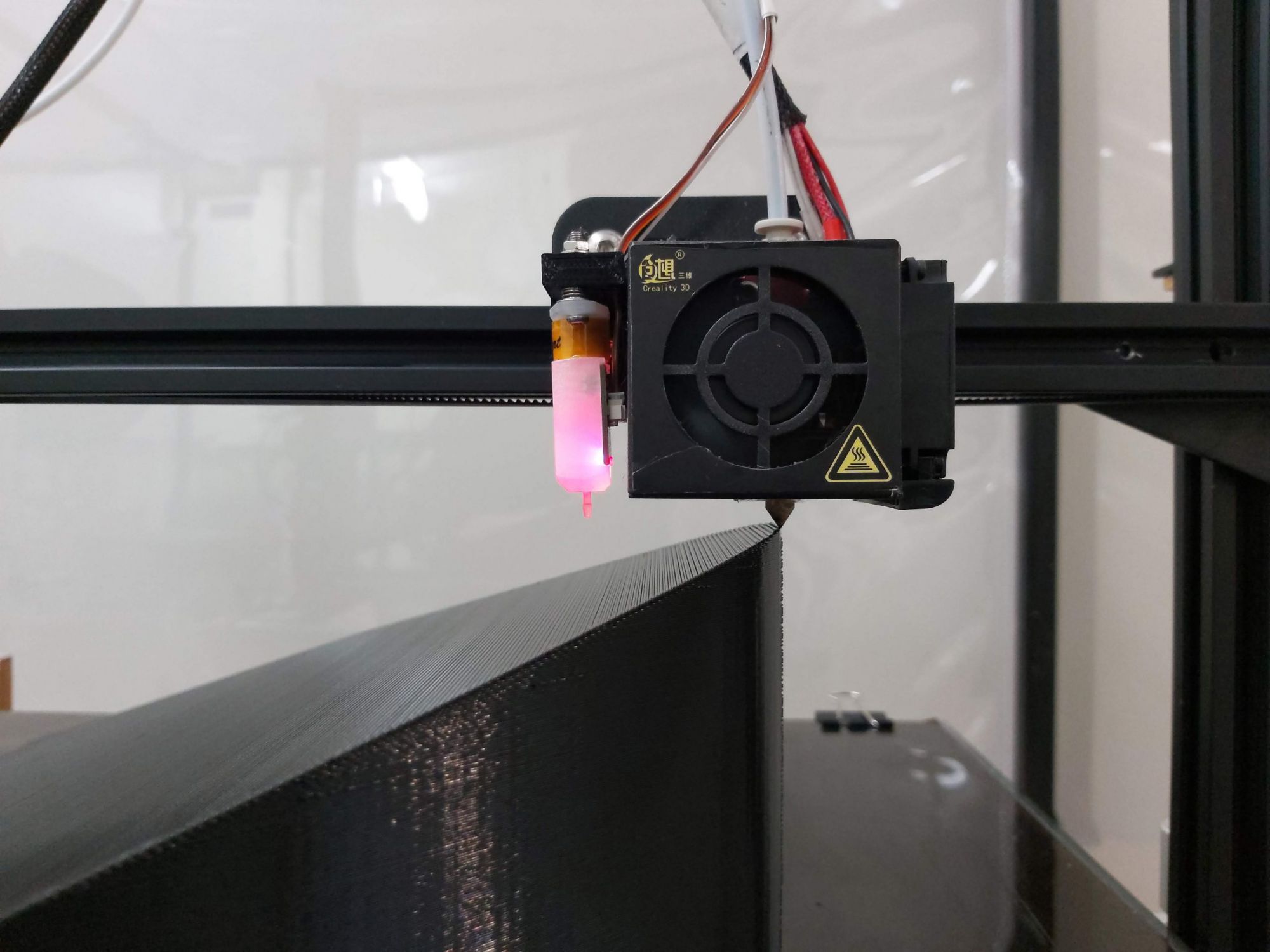

3D printing represents an advanced construction method that has allowed the Yachting Developments team to blend traditional skills with modern, cutting-edge technology, while also delivering time and cost saving benefits across the build process. With versatile application options, Yachting Developments has been able to use its 3D printing technologies on a wide range of projects.

“Over the past three years we have developed and invested in our printing and moulding capabilities, including our advanced 3D printing set up,” says Ian Cook, Managing Director of Yachting Developments.

“To date we have made use of this 3D printing technology on architectural and movie set projects and are excited to now be putting it to use in the marine field as well.”

The Yachting Developments 3D printing division was recently put to work in a marine setting when creating the tooling for the all-new AC9F model, the proposed boat for the upcoming Youth America’s Cup that is due to be hosted in Auckland as part of the 36th America’s Cup.

“The creation of the first boat and its appendages has been a good blend of traditional boat building and leading edge printing and moulding,” says Cook.

“The use of 3D printing allowed the prototype to be built without the need for plugs, which helped to speed up the build time and improved cost and accuracy for the short production run.”

The first AC9F model – christened Kõtare (meaning kingfisher in Maori) – was completed by Yachting Developments in March 2020, with initial sea trials currently underway.