New generation power

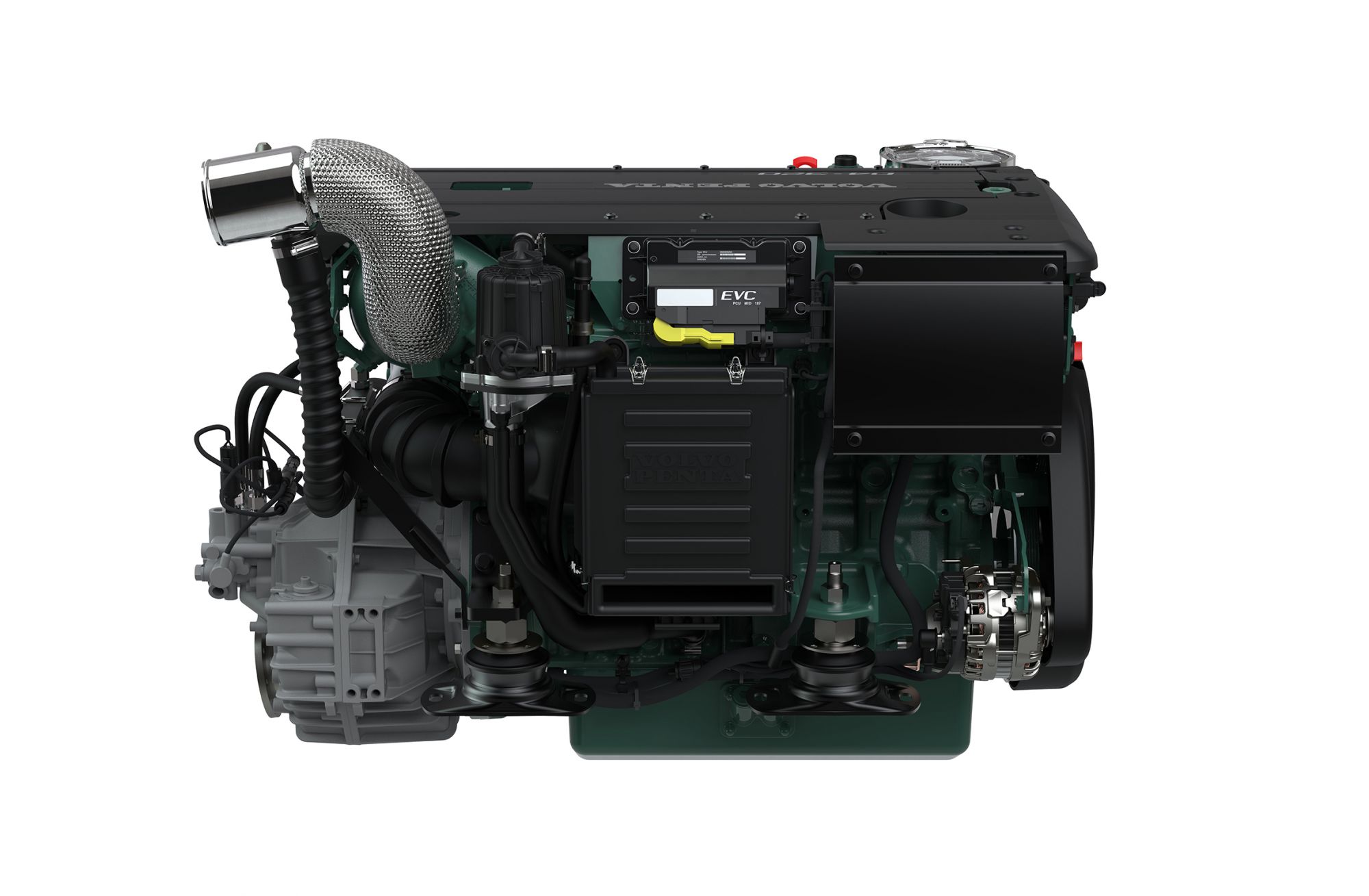

Volvo Penta showcased new generation D4 and D6 marine engines, among other innovations, at this year’s Sydney International Boat Show.

Photography by Volvo Penta

03 August 2019

Volvo Penta’s proven D4 and D6 marine engines, available from 150 to 480 hp, have had a full update to deliver more power, increased reliability and lower cost of ownership.

With over 100,000 units already powering boats worldwide, the new generation D4 and D6 engines are set to extend Volvo Penta’s technical advantages even further.

The 3.7 litre D4 and the 5.5 litre D6 engines are designed and built solely for marine purposes.

A large portion of the engines have been reengineered to deliver on the increasing demand for greater reliability and more powerful engines.

Available from 150 to 480 hp, these engines are part of fully integrated systems – from helm to prop – perfectly matched to transmissions covering IPS, Aquamatic sterndrive, shaft and water-jet installations.

“The list of performance upgrades are lengthy and includes a new engine management system, new fuel injection system, new turbocharger and a new supercharger,” says Petter Andolf, Chief Project Manager for the D4/D6.

“The cylinder head, pistons, and valves are reengineered to withstand higher torque, as well as meeting higher reliability and durability requirements.”

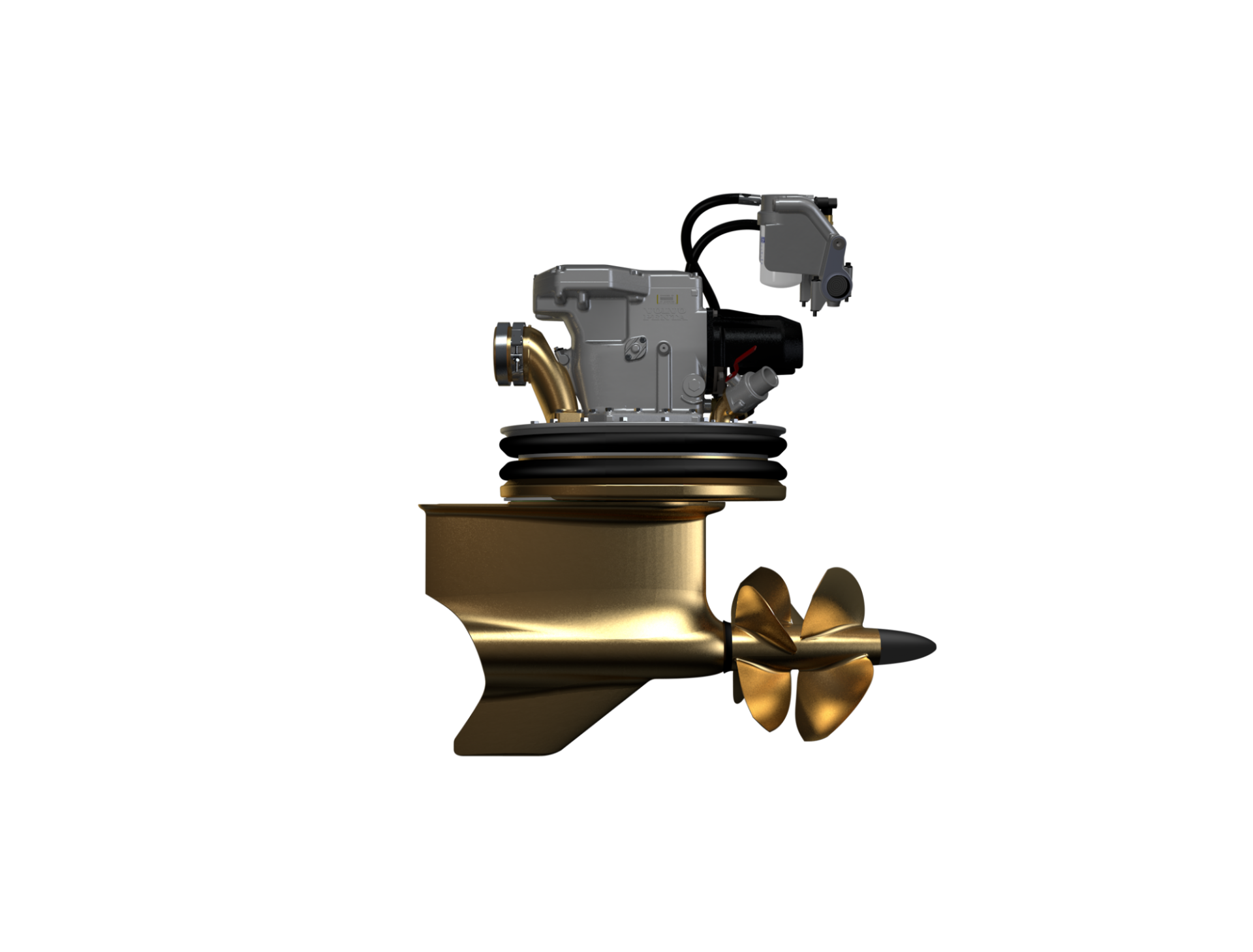

The company also unveiled an upgraded Inboard Performance System (IPS) and a brand new Aquamatic sterndrive (DPI).

Volvo Penta has matched the latest in advanced engineering with customer feedback to propel its premium marine driveline systems into a new era of high performance, cost-effective and enjoyable boating.

Now offering a host of advanced engineering and technology upgrades that lower the cost of ownership and increase performance and reliability – not to mention allow future tech to be incorporated – Volvo Penta’s market-leading IPS and DPI driveline systems set the bar even higher in the marine sector.

Not only that, new manufacturing technology and design concepts also allow for a longer service life of the drive, with less maintenance.

Volvo Penta Inboard Performance System (IPS) was a revolution in marine technology when it was launched in 2005.

With 25,000 in the market, the company is now using its wealth of knowledge to upgrade the IPS to offer more power and enhanced capabilities to customers.

The system’s innovative design has forward-facing, twin counter-rotating propellers that sit below the hull for incredible ‘grip’ of the water. With the individual steerable pods controlled by the joystick, the IPS provides superior handling and maneuverability, but the system also provides higher performance, lower fuel consumption and less noise and vibrations, compared to a conventional inboard shaft installation.

The IPS package provides up to 30 percent lower fuel consumption compared to inboard shaft installations, up to 15 percent faster acceleration and 20 percent higher top speeds.

Noise and vibration levels are also reduced, by up to 50 percent. An IPS package can be installed in twin, triple or quadruple configurations.

The Volvo Penta new generation Electronic Vessel Control system was another innovation exhibited at this year’s boat show. The sophisticated Electronic Vessel Control (EVC) system has been designed with the complete boat in mind.

With an all-new electrical architecture, the upgraded EVC system (EVC2) offers new features, such as a single connection point and the possibility to manage EVC functions for the complete vessel and driveline independently.

When Volvo Penta’s pioneering Electronic Vessel Control (EVC) system was first launched in 2003, it was the height of innovation – and has remained so ever since. It has established itself as the benchmark thanks to introductions such as Joystick Docking, Dynamic Positioning System and Glass Cockpit.

The EVC system has enabled the company to integrate these systems throughout the boat, delivering on Volvo Penta’s easy boating philosophy – making the boating experience easier and more accessible.

“The EVC system connects and manages the internal communications between the engine and driveline, levers and display screen – giving vessel owners integrated functionality and simpler operation,” says Jonas Welinder, Production Planner, Marine Electronics at Volvo Penta.

With the introduction of EVC2, the system gets a major update with a new electrical architecture that ensures faster software download, improved diagnostics and traceability, as well as offering the prospect of upgrading to additional functionality in the future.

A key new feature is the On-Board Maintenance Assistant, which informs users of service dates, as well as keeping track of past servicing and diagnostic information, with a real-time clock.

Volvo Penta has also introduced steer-by-wire as a standard on both single and twin installation of the new DPI drive – eliminating the need for hydraulic fluid at the helm and making available EVC features, such as Low speed and DPS (Dynamic Positioning System) to a wider range of applications.

The EVC2 platform now has only a single connection point, regardless of how many engines are in the installation. This offers greater ease of maintenance, as well as enhanced software downloads and diagnostics.

More product information and dealer contacts here.