Plotting the way

WASSP now protecting 1500 metres worth of superyachts globally.

26 June 2019

Exploring new waters, and creating their own charts has seen WASSP Multibeam Sonar Systems become ‘must have’ equipment for superyacht owners with WASSP systems now protecting over 1500 metres of superyachts globally.

WASSP Multibeam Sonars are now installed onto superyachts from some of the worlds leading builders, including vessels from Amels, Damen, Feadship, Lurssen, Sunseeker, Fincantieri, Oceanco, Abeking and Rasmussen. Vessels as small as 29 metres through to over 190 metres in length.

With the growth in owners, guests and crew wanting to explore new locations, explore new fishing spots, diving wrecks and reefs, keeping the yacht safe at new undiscovered anchorages is a growing concern for captains around the world.

WASSP W3 (Wireless) is ideally suited to use when navigating in unknown waters or where marine charts lack sufficient detail, WASSP W3 takes the risk out of the equation for the captains of these large and very expensive vessels.

“WASSP multibeam provides captains the confidence to try different locations, allowing them to build their own bathymetric maps and use them to navigate, knowing they can trust them,” says WASSP Global Sales & Marketing Manager Rufus Whiteford.

“Yacht owners are wanting to explore more with their vessels, and get off the beaten track so to speak.

Detailed bathymetric data allows for yachts to safely enter bays, lagoons, fjords or any area where depth information is not available or unreliable.”

“We are experiencing increased enquiry levels from Captains and owners looking for the latest in sonar technology and with that are now seeing the systems installed on a large number of vessels globally – totalling 1500 metres of yacht length.”

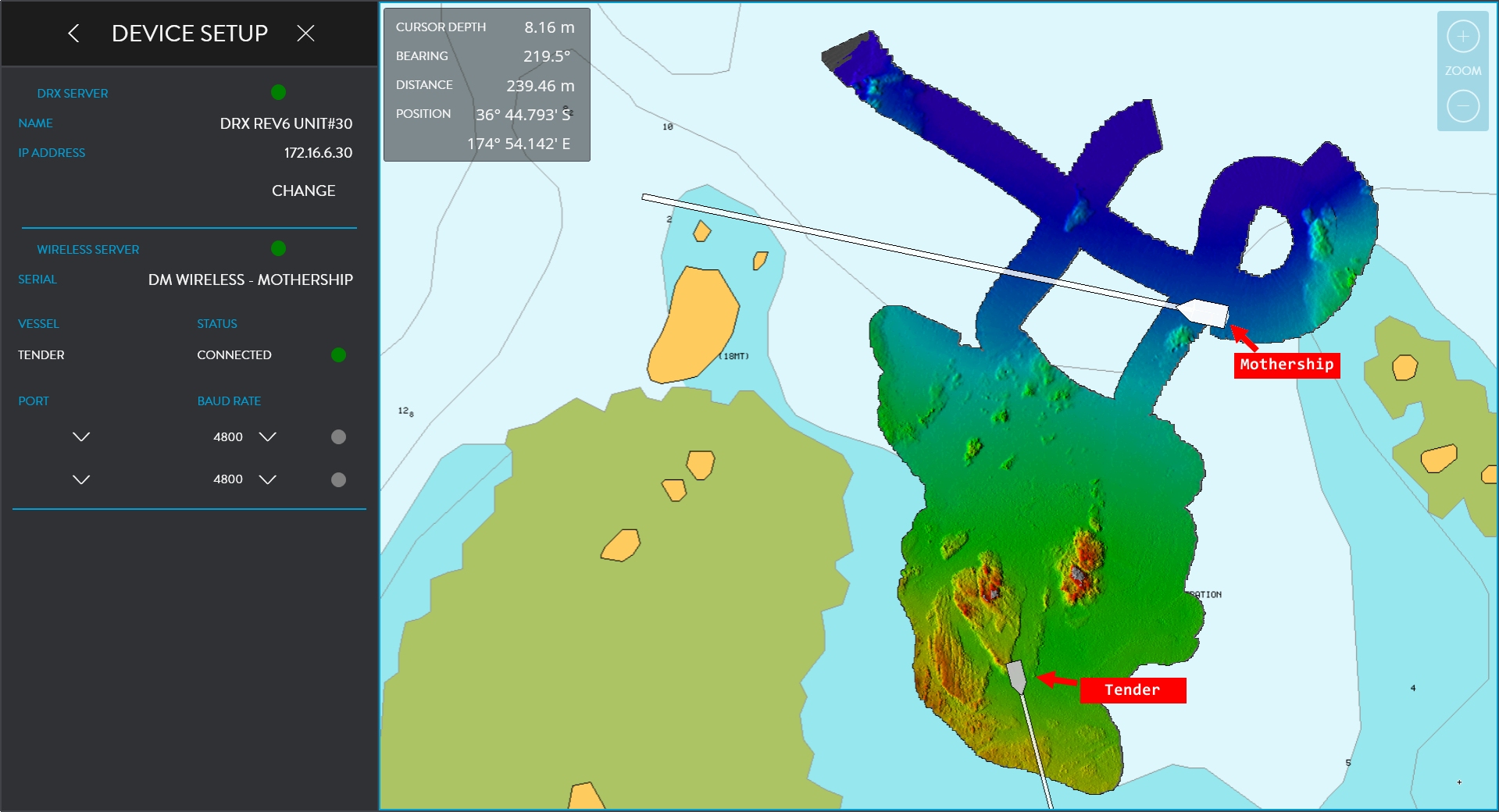

Installed in the tender or support vessel of a superyacht, the W3 uses a wireless link to send a real-time sea floor map back to the super yachts bridge system and display on a MaxSea navigation plotting platform – all in real-time.

One of the major advantages of W3 is that the main equipment is installed in the tender so there is very little interruption in day to day operations of the mother ship or the need to go into drydock. Such is the simplicity of the system that some have even been installed by yachts crew with WASSP engineers just involved in commissioning and training.

Once installed and thanks to the very wide swath width and hundreds of beams the seafloor can be mapped quickly and in high resolution. A standard echosounder only measures one point at the time, whereas WASSP Multibeam measures 224 points at the time over a coverage of 120 degrees.