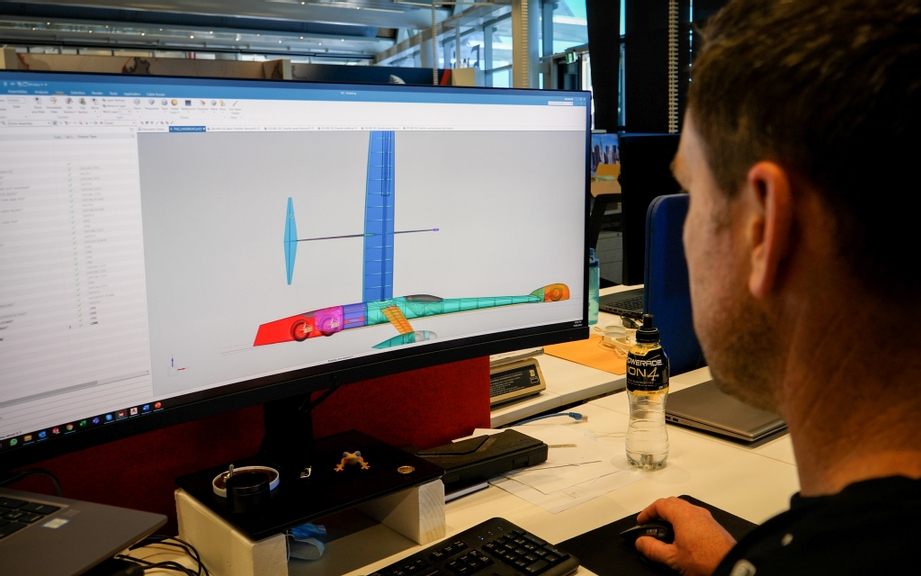

ETNZ Project Speed progress

Emirates Team New Zealand Wind Powered Land Speed project is using innovative build materials.

23 March 2022

The Emirates Team New Zealand Wind Powered Land Speed project is putting considerable thought into build materials.

“In the design process when we’re trying to determine just how we’re going to build all of these parts, the build team plays a major role,” says Mechanical Engineer Tim Meldrum.

“We all sit around a table, thrashing out just what the process will be.”

The Emirates Team New Zealand boat building team, based in the ETNZ production facility on Auckland North Shore, are in charge of the build. It includes a mix of young apprentices and some of the most experienced boat builders in the New Zealand marine industry.

They know all about the materials used in their trade and when it comes to composites, there are two main options of construction. A pre-impregnated carbon fibre and dry fibre with a wet laminate.

“As the name suggests, pre-preg is carbon fibre pre-impregnated with resin,” says boat builder Kurt Riechelmann.

“We would usually use pre-preg because you get perfect resin ratios out of it and it’s not until it gets hot that the resin will flow. It’s almost like laying down dura-seal.”

However pre-preg isn’t cheap. Users need to consider the costs and weight ramifications.

Emirates Team New Zealand build their AC75 hulls from pre-preg, since a small saving over a larger area such as a boat hull can be heavy. It also allows the team to hit strict weight limits in the AC75 class rule.

A lighter hull structure gives you more freedom to develop systems within the hull weight limit.

In the case of the land speed yacht, the pre-preg composites are reserved exclusively for what’s in the air above the craft.

“We can be a bit more focused where we push the tech,” explains Meldrum.

“So, the mast, the wing, the spar, if we make that heavy it steals the righting moment and the stability that you need to generate power. We are more weight conscious,” he continues.

When asked about the main fuselage, Meldrum knew what he was talking about.

“We’ll add some ballast for downforce grip in the main body, so it is much less sensitive to weight than the wing,” he says.

“Therefore, with the land speed record craft the body is less mass critical, the weight is down low and doesn’t affect righting moment too much. Pre-preg does not justify itself in this case, so the smarter move is to save time and money and use dry fibre infusion and wet laminate.”

Some of the main body elements lend themselves nicely to the infusion process, where multiple layers of carbon are placed in a mould dry. Then, a vacuum created within a bag and resin is released, which flows into the carbon to cure as a rigid part.

This process is great for thicker laminates without core. This is because the laminating process is done dry, meaning there’s no time pressure from resin curing.

For the production team it’s a faster, more user-friendly option than pre-preg during construction. It takes approximately a quarter of the time to lay up the body of the land speed craft with this process compared to using pre-preg.

However, because it’s a slightly heavier way of laminating carbon, it’s much harder to achieve the optimum resin to fibre ratio.

“Infusion is a bit of a dark art,” says veteran ETNZ boat builder Peter Ockleston.

“It can go wrong, but with the processes we’ve been working on over the last 15 years or so, we’ve gotten pretty close to getting it right every time.”

It is this talent and knowledge that the whole team relies on in the ETNZ production facility.

“It’s nice to have a real depth of experience within our build team so we can draw upon all forms of manufacture,” says Meldrum.

“We can pick the process that best suits the part, no matter what it is.”